Description

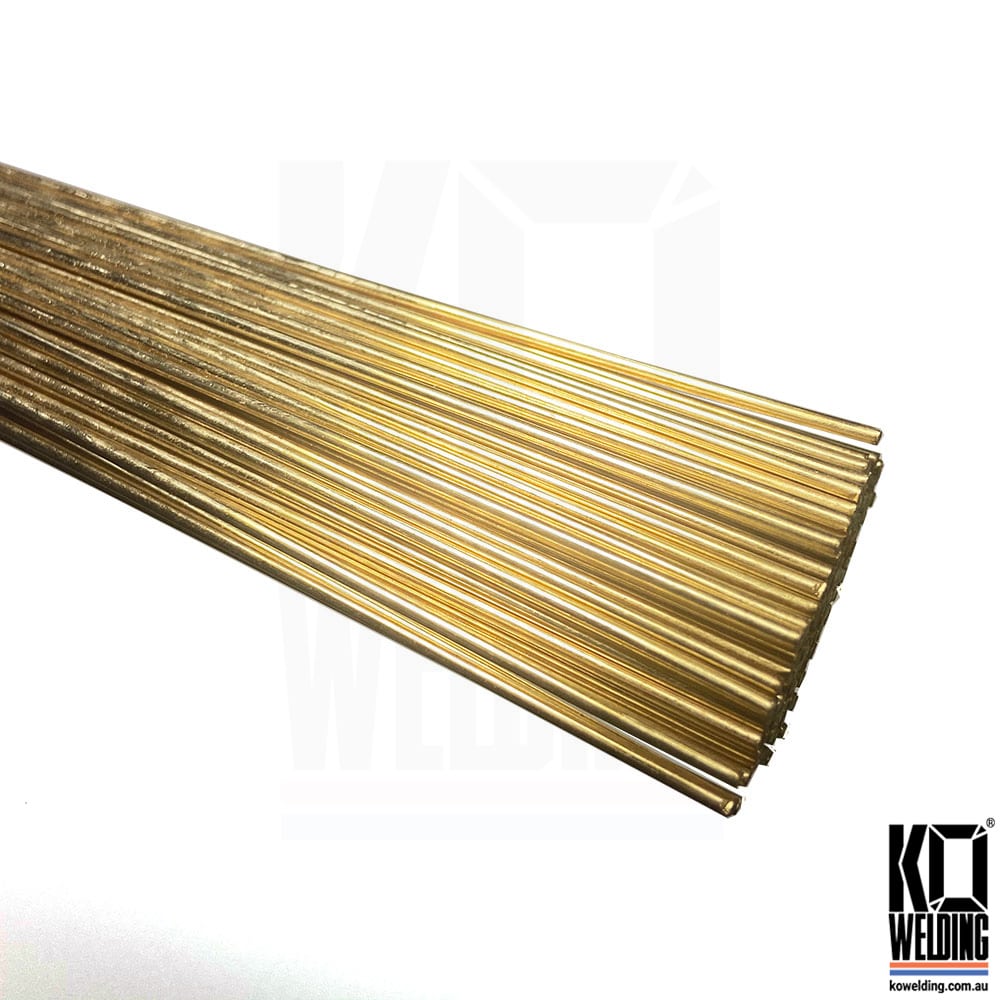

Class: ERCuSi-A

AWS: A5.7

Conforms to Certification: AWS – 5.7 ASME SFA A5.7

Silicon Bronze: Tig Welding Process (GTAW)

| AWS Chemical Composition Requirements | |

| Cu = Remainder | Zn = 1.0 max |

| Sn = 1.0 max | Mn = 1.5 max |

| Fe = 0.50 max | Si = 2.8 – 4.0 |

| Al = 0.01 max | Pb = 0.02 max |

| Other = 0.50 max | |

Application

Use for welding of Silicon Bronze Copper, or Aluminum Bronze of low aluminum content. It can also be used for brazing malleable iron and light gauge steel.

Deposited Chemical Composition % (Typical)

Dependent on weld process

(Nominal) All Weld Metal Properties Requirements

Tensile Strength 50,000psi

Preheat / Interpass Recommendations

When working with silicon bronze base metal keep the inter-pass temperature below 65° C to minimize hot cracking. Base metals of cast iron may need a preheat of 315° C while copper may need 200-400° C.

![[ER309L] 5KG METER LONG | Stainless TIG Filler Rod | 1.2mm](https://kowelding.com.au/wp-content/uploads/2022/08/1.2mm-309.jpg)

![[ER309L] METER LONG | Stainless TIG Filler Rods | 1.6mm/2.4mm/3.2mm](https://kowelding.com.au/wp-content/uploads/2021/03/309-1m.jpg)

![[ER316LSi] METER LONG | Stainless TIG Filler Rod | 1.6mm/2.4mm/3.2mm](https://kowelding.com.au/wp-content/uploads/2020/12/316-1m.jpg)

Finally restocked. Great stuff, like hot glue for men!

I needed these for a job I have coming up. Not a big job, but an important one. I should have had these in stock, but due to an oversight, I was unable to complete the welding. KO Welding supplied these, and the quality of these rods is excellent. I was expecting to pay a lot more, but as always, KO Welding are not only the goto for supplies, they are also affordable. These rods are simply first rate quality.

Great service.